Um unvorhergesehene Stillstände durch verdeckten Spindelverschleiß zu vermeiden, hat die M-Group der KU Leuven gemeinsam mit CTRL Engineering einen innovativen Spindelprüfstand entwickelt – den Spindle Listener. Dieser soll Verschleiß frühzeitig erkennen, die Lebensdauer von Maschinen somit verlängern und die Betriebssicherheit erhöhen.

Die Herausforderung bestand darin, minimale Veränderungen im Spindelverhalten messbar zu machen. Die Lösung: Ein vollintegriertes Testsystem, das reale Bewegungszyklen unter Laborbedingungen ausführt und dabei präzise Datensätze für prädiktive Wartungsmodelle gewinnt.

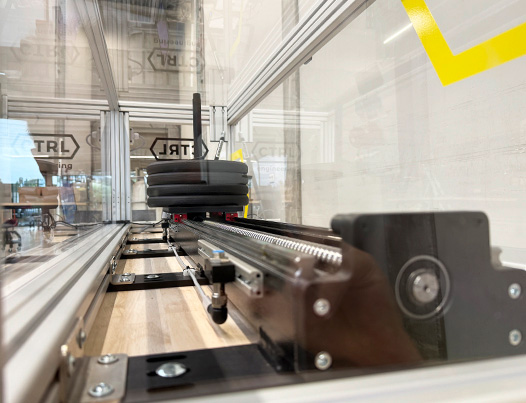

Dank der Vermittlung und engen Zusammenarbeit mit Vansichen Lineartechnik sorgen unsere HIWIN-Profilschienenführungen, Servomotoren und Antriebsverstärker mit ihrer Zuverlässigkeit und Genauigkeit für präzise und dynamische Bewegungen der Spindel. Auch bei hohen Geschwindigkeiten gewährleisten sie höchste Wiederholgenauigkeit und stabile Performance und bilden dadurch die Basis für die präzise Bewegungssteuerung des Prüfstands.

Wir freuen uns ganz besonders mit unserer Antriebstechnik Teil dieses Projekts zu sein und wissenschaftliche Forschung zu unterstützen, sowie den Weg von der reaktiven zur proaktiven Wartung zu ebnen.